how to do do bevel cuts with laser engraving machine

How to Do Bevel Cuts with a Laser Engraving Machine

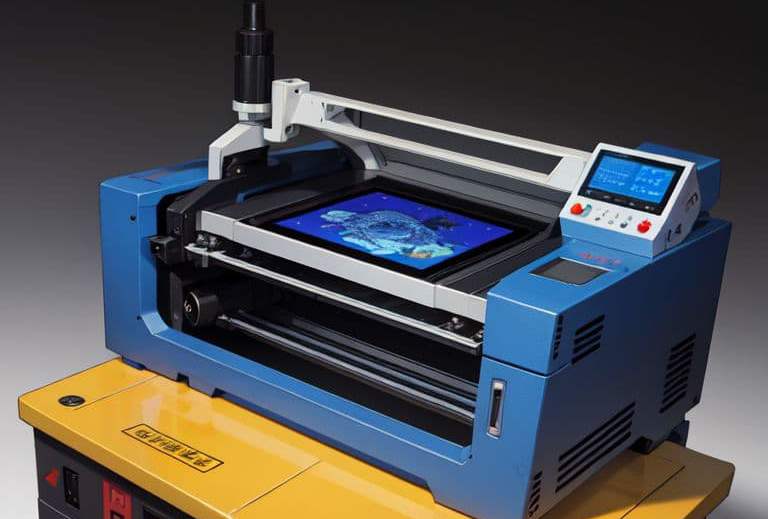

Laser engraving machines have revolutionized the way we approach precision cutting and engraving tasks. One of the advanced techniques you can achieve with a laser engraver machine is bevel cutting. Bevel cuts add a sophisticated touch to your projects, providing angled edges that can enhance the aesthetic appeal of your work. In this guide, we will walk you through the process of performing bevel cuts using a laser engraver machine.

Understanding Bevel Cuts

What Are Bevel Cuts?

Bevel cuts are angled cuts made along the edge of a material. Unlike straight cuts, bevel cuts are slanted, which can add depth and dimension to your projects. These cuts are commonly used in various applications, including signage, decorative items, and custom parts.

Why Use a Laser Engraver Machine for Bevel Cuts?

A laser engraver machine offers unparalleled precision and control, making it an ideal tool for bevel cuts. The laser beam can be adjusted to cut at specific angles, ensuring consistent and accurate results. Additionally, the non-contact nature of laser engraving protects the material’s surface from scratches and other damage.

Preparing for Bevel Cuts

Selecting the Right Material

Before you start, choose a material that is suitable for laser cutting. Common materials include wood, acrylic, and certain metals. Ensure that the material can withstand the high temperatures generated by the laser beam.

Setting Up the Laser Engraver Machine

Connect your laser engraver machine to a computer and import the design file that includes the bevel cuts. Make sure to calibrate the machine and adjust the laser settings according to the material you are using. This includes setting the appropriate power, speed, and focus distance.

Executing Bevel Cuts

Adjusting the Laser Angle

To achieve bevel cuts, you need to adjust the angle of the laser beam. Some advanced laser engraver machines come with adjustable laser heads that can be tilted to the desired angle. If your machine does not have this feature, you can create a jig to hold the material at an angle.

Performing the Cut

Once the laser angle is set, initiate the cutting process. Monitor the machine closely to ensure that the cuts are being made at the correct angle and depth. Make any necessary adjustments to the laser settings to achieve the desired bevel effect.

Post-Cutting Procedures

Cleaning the Edges

After completing the bevel cuts, inspect the edges for any residue or imperfections. Use a soft brush or cloth to clean the edges. If necessary, you can sand the edges lightly to smooth them out.

Finishing Touches

Depending on your project, you may want to apply a finish to the bevel cuts. This could include painting, staining, or applying a protective coating. Ensure that the finish enhances the appearance of the bevel cuts and complements the overall design.

Conclusion

Bevel cuts can significantly enhance the visual appeal of your projects, and a laser engraver machine is the perfect tool to achieve them. By understanding the process and following the steps outlined in this guide, you can create precise and attractive bevel cuts with ease. Whether you are working on a professional project or a personal craft, mastering bevel cuts with a laser engraver machine will open up new possibilities for your creative endeavors.