how long does laser engraver machine last in africa

Enhancing the Lifespan of Laser Engraver Machines in Africa

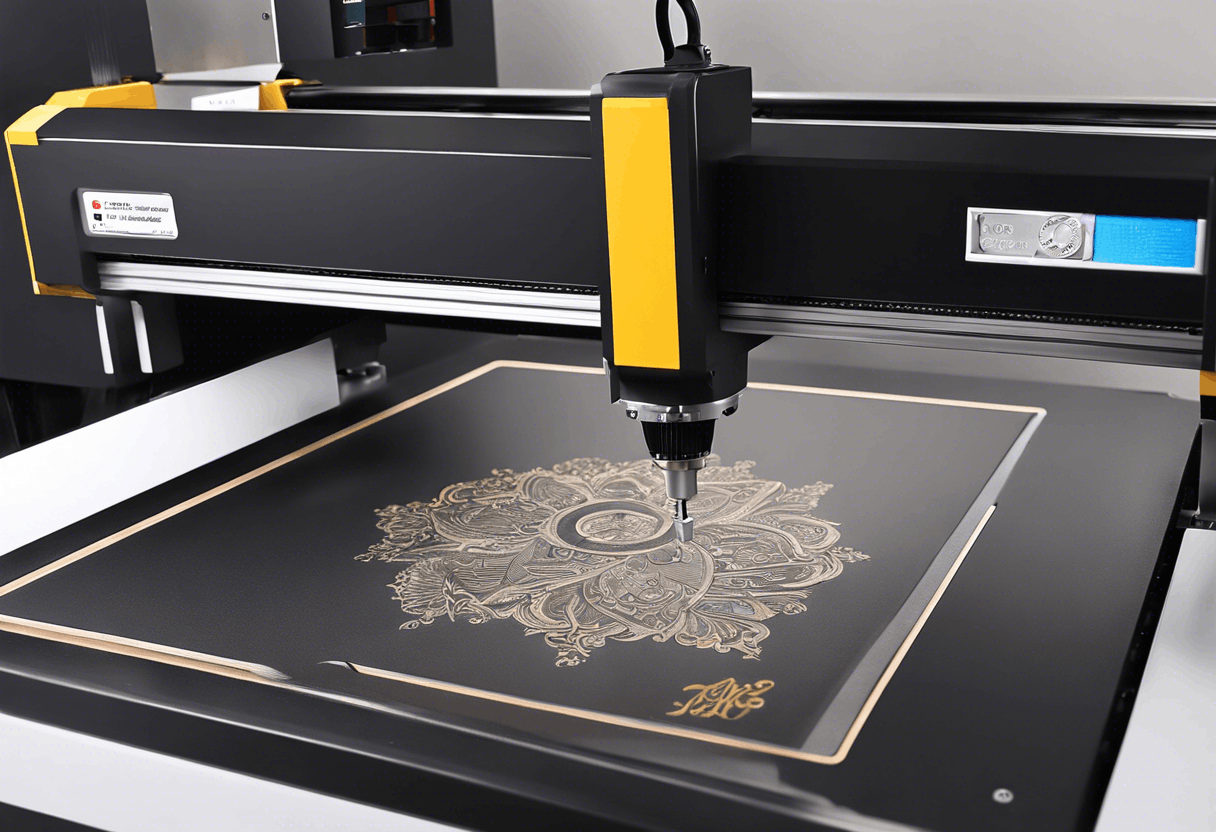

How long a laser engraver machine lasts will depend on whether you can operate the machine correctly and whether you regularly maintain its components and parts. A laser engraver kit has many parts, with each one playing an indispensable role. At present, most common laser engraving machines are composed of five parts: a control system, transmission system, optical system, auxiliary system, and a mechanical platform.

Understanding the Key Components of a Laser Engraver Machine

The mechanical system of a laser engraver machine is composed of mechanical accessories, such as a guide rail, cover, mirror frame, and so on. Its auxiliary system is composed of air compressors, water pumps, and exhaust fans. The transmission system consists of linear guides, stepping motors, belts, and gears. Finally, the optical system consists of a power supply, laser tube, mirrors, and a lens. Each of these components has a certain service life. In this article, we will mainly discuss the lifespan of the laser tube and lens, as well as explain how to extend the service life of the whole laser engraving machine.

Laser Tube Lifespan

The laser tube is a key component of any laser engraver machine, meaning that its lifespan has become the most important purchase indicator for users. Many users work with their laser engraver machine for 8 to 10 hours a day, meaning that the damage to the laser tube and other key components is significant. In these circumstances, a laser tube that should have been used for more than a year is often scrapped after only half a year. So, how long should a laser tube be able to work continuously before needing to be replaced?

The general life of a laser tube is 5,000-10,000 hours. In the state where the current ratio is relatively small, it would not be a problem for the laser tube to continuously emit light for 4 hours. In this instance, the laser tube itself will not become too damaged. However, when the laser tube is used continuously for over 4 hours, the temperature inside the laser tube will gradually increase. When the speed of the temperature rise exceeds the speed of heat dissipation in the laser tube, then the load of the laser tube will increase and the laser tube will be made to work continuously under high temperature conditions. In this instance, the lifespan of the laser tube will decline rapidly.

Laser Lens Lifespan

The laser lens is another crucial component of a laser engraver machine. The lifespan of the laser lens largely depends on the quality of the lens and the working environment. Dust, smoke, and other contaminants can significantly reduce the lifespan of the laser lens. Regular cleaning and maintenance are essential to ensure the longevity of the laser lens.

Typically, a high-quality laser lens can last between 1,000 to 2,000 hours of operation. However, this can vary based on the frequency of use and the maintenance practices followed. Ensuring that the working environment is clean and free from contaminants can help in extending the lifespan of the laser lens.

How to Extend the Service Life of a Laser Engraver Machine?

Regular Maintenance

Regular maintenance is crucial for extending the lifespan of a laser engraver machine. This includes cleaning the laser lens, checking the alignment of the laser tube, and ensuring that all mechanical parts are well-lubricated. Regularly inspecting and replacing worn-out parts can prevent major breakdowns and extend the overall lifespan of the machine.

Proper Usage

Proper usage of the laser engraver machine is essential for its longevity. Avoid running the machine continuously for long hours without breaks. Allowing the machine to cool down can prevent overheating and reduce the wear and tear on critical components. Additionally, following the manufacturer’s guidelines for operation can help in maintaining the machine in optimal condition.

Environmental Control

Controlling the working environment can also play a significant role in extending the lifespan of a laser engraver machine. Keeping the workspace clean and free from dust and contaminants can prevent damage to the laser lens and other sensitive components. Using air filters and exhaust systems can help in maintaining a clean working environment.

Quality Components

Investing in high-quality components can also contribute to the longevity of a laser engraver machine. High-quality laser tubes, lenses, and other parts may have a higher initial cost but can provide better performance and a longer lifespan, ultimately saving costs in the long run.

Conclusion

The lifespan of a laser engraver machine in Africa, or anywhere else, depends on various factors including the quality of components, maintenance practices, and usage patterns. By understanding the key components and following best practices for maintenance and operation, users can significantly extend the service life of their laser engraver machines. Regular maintenance, proper usage, environmental control, and investing in quality components are essential steps to ensure that the laser engraver machine remains in optimal condition for years to come.