how to design for 3d laser engraving on z-tech machine

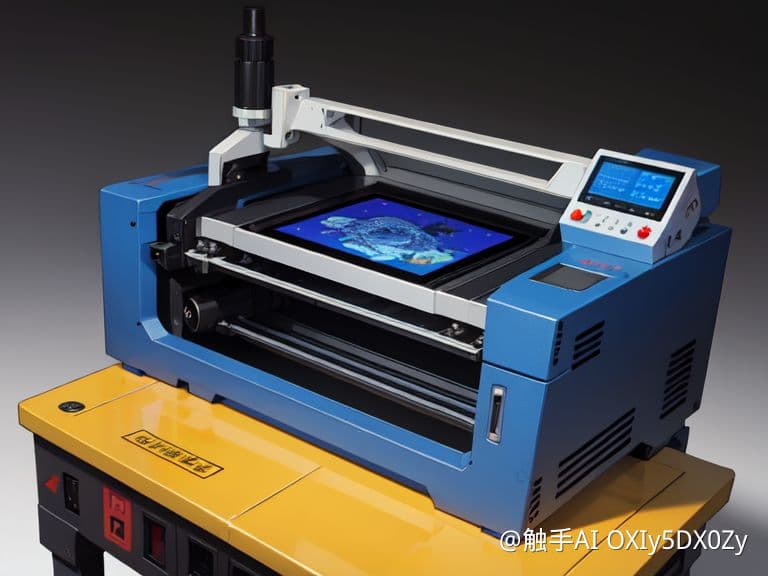

How to Design for 3D Laser Engraving on Z-Tech Machine

Designing for 3D laser engraving on a Z-Tech machine can be a rewarding experience, allowing you to create intricate and detailed designs with precision. This guide will walk you through the essential steps and considerations to ensure your designs are optimized for the laser engraver machine.

Understanding the Basics of 3D Laser Engraving

Before diving into the design process, it’s crucial to understand how a laser engraver machine operates. A laser engraver machine uses a high-power density laser beam to modify the material’s surface, creating detailed and precise engravings. The laser beam’s interaction with the material varies depending on the material’s properties, such as its melting point.

Preparing Your Design

Choosing the Right Software

To create designs for a laser engraver machine, you need software that supports vector graphics. Popular choices include Adobe Illustrator, CorelDRAW, and AutoCAD. These programs allow you to create detailed vector files that the laser engraver machine can interpret accurately.

Creating Vector Files

When designing for 3D laser engraving, it’s essential to use vector files. Vector graphics are composed of paths defined by mathematical equations, ensuring that your design remains crisp and clear at any size. Save your designs in formats such as .AI, .SVG, or .DXF.

Designing for Depth

3D laser engraving involves varying the depth of the engraving to create a three-dimensional effect. Use shading and gradients in your design to indicate different depths. Darker areas will be engraved deeper, while lighter areas will be shallower.

Setting Up the Z-Tech Laser Engraver Machine

Connecting the Machine

First, connect your Z-Tech laser engraver machine to your computer. Ensure that the machine’s drivers and software are correctly installed. This connection allows you to transfer your design files to the machine for engraving.

Calibrating the Machine

Proper calibration is crucial for achieving accurate engravings. Calibrate the laser engraver machine by adjusting the focus, speed, and power settings. These settings will vary depending on the material you’re using and the desired depth of the engraving.

Material Selection

Different materials react differently to laser engraving. Common materials include wood, acrylic, glass, and metal. Each material requires specific settings on the laser engraver machine to achieve the best results. Conduct test engravings on scrap pieces to fine-tune your settings.

Engraving Process

Importing Your Design

Once your design is ready and the machine is calibrated, import your vector file into the laser engraver machine’s software. Ensure that the design is correctly positioned on the material to avoid any misalignment during the engraving process.

Running the Engraving

Start the engraving process by initiating the laser engraver machine. Monitor the process closely to ensure that the machine is operating correctly and that the engraving is proceeding as expected. Make any necessary adjustments to the settings if you notice any issues.

Post-Engraving Considerations

Cleaning the Engraved Material

After the engraving is complete, clean the material to remove any residue or debris. Use a soft brush or cloth to gently clean the surface without damaging the engraving.

Finishing Touches

Depending on the material and the desired finish, you may want to apply additional treatments such as varnishing, painting, or polishing. These finishing touches can enhance the appearance and durability of your engraved design.

Conclusion

Designing for 3D laser engraving on a Z-Tech machine involves a combination of creative design and technical precision. By understanding the capabilities of your laser engraver machine and following the steps outlined in this guide, you can create stunning and intricate engravings with ease. Experiment with different materials and settings to discover the full potential of your laser engraver machine.