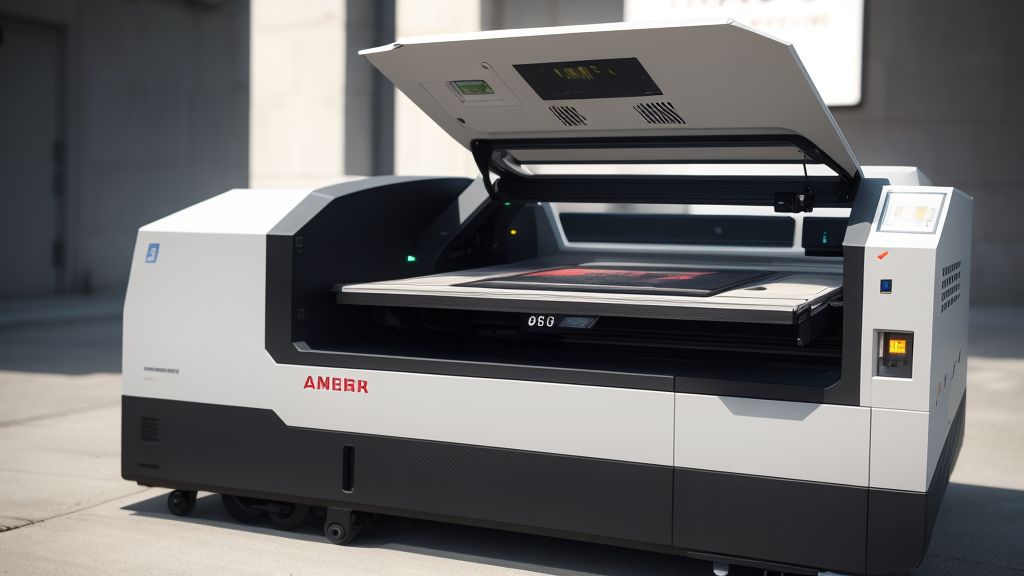

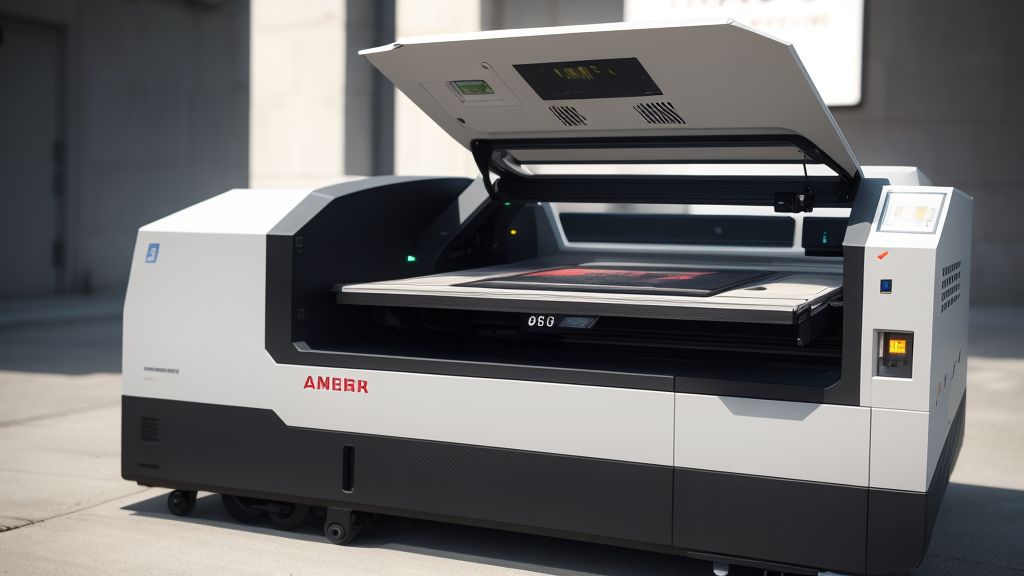

What is the difference between a laser cutter and a laser engraver?

Laser cutters and laser engravers are both tools that use laser technology to manipulate materials, but they serve different primary functions and have some variations in their capabilities and applications. Here’s a detailed look at the differences between a laser cutter and a laser engraver:

1. Primary Function

- Laser Cutter: Primarily designed to cut through materials. It uses a high-powered laser beam to make precise cuts by melting, burning, or vaporizing the material. Laser cutters are typically used to create parts, components, or decorative designs from flat sheets of material like metal, wood, plastic, fabric, or acrylic.

- Laser Engraver: Focused on removing parts of the surface layer of a material to create designs, texts, or images. The engraving process involves using a less intense laser than cutting to etch or mark the surface without cutting all the way through (unless intended for deep engraving).

2. Power and Intensity

- Laser Cutters: Generally equipped with more powerful lasers because they need enough energy to completely penetrate materials. The power can range widely depending on the type of material and thickness being cut.

- Laser Engravers: Use lower power settings since the objective is usually only to alter the surface of the material rather than to cut through it entirely.

3. Precision and Depth Control

- Laser Cutter: Offers high precision in cutting shapes and designs but is primarily concerned with slicing through material along defined paths.

- Laser Engraver: Provides fine control over depth modulation which allows for detailed shading and texturing effects that are not typically achievable with standard cutting processes.

4. Material Compatibility

- Both tools can work with a variety of materials including metals (specifically with fiber lasers), wood, plastics, leather, and more. However:

- Laser Cutters might be preferred for thicker materials where full penetration is required.

- Laser Engravers are often used for delicate or thin materials where only surface marking is needed.

5. Applications

- Laser Cutters: Commonly used in manufacturing for making parts out of sheet metal, building models from various mediums in architecture or design industries, creating intricate patterns in woodworking projects, etc.

- Laser Engravers: Widely used for personalization purposes such as engraving names or logos on products (e.g., trophies, gifts), adding barcodes or serial numbers to industrial products for tracking purposes, creating artwork on various surfaces.

Conclusion

While both laser cutters and engravers utilize similar technology—focused light beams controlled by computer numerical control (CNC)—their applications differ significantly based on their power levels and operational focus (cutting vs. marking/engraving). Understanding these differences helps users select the right tool based on their specific needs whether it’s cutting through thick plates of steel or delicately etching designs onto wooden plaques.