how often do you clean laser engraving machine

How Often Do You Clean a Laser Engraving Machine?

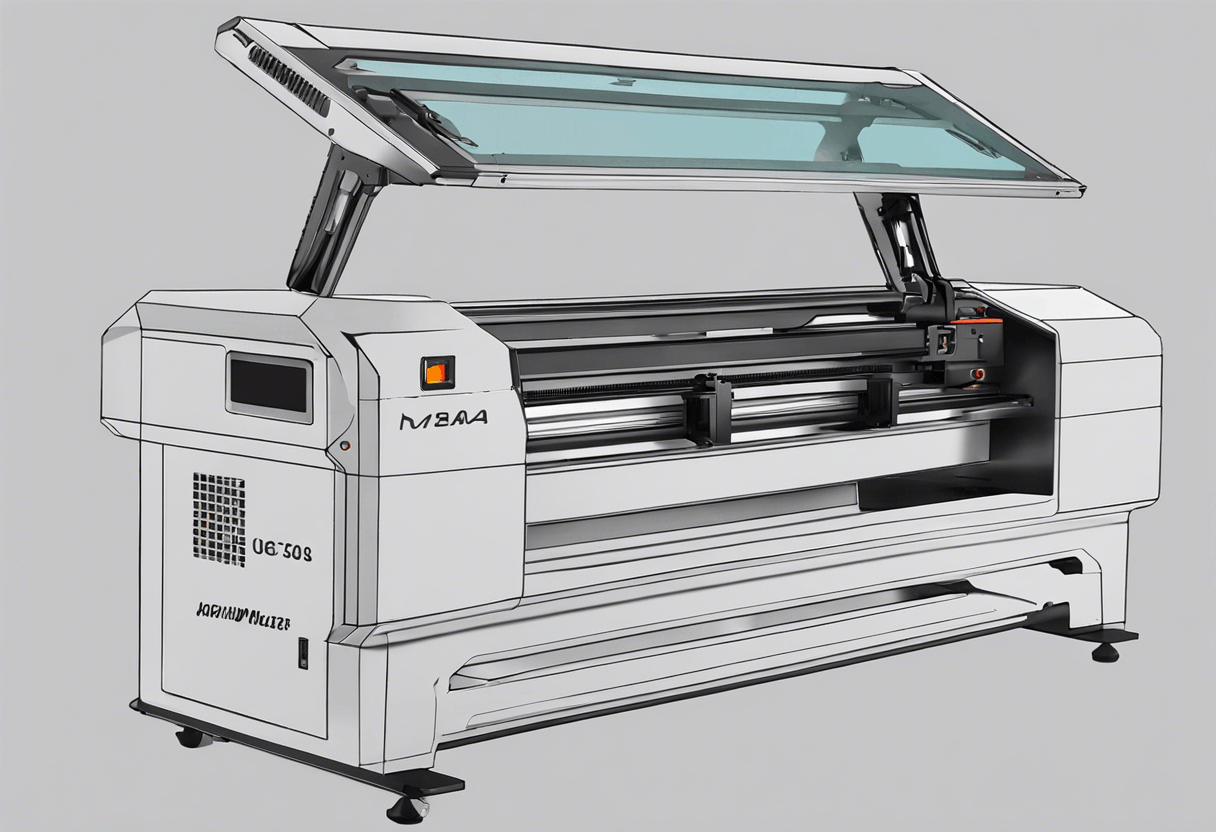

Maintaining a laser engraver machine is essential for ensuring its longevity and optimal performance. Regular cleaning and maintenance can prevent potential issues and extend the service life of your equipment. But how often should you clean your laser engraver machine? This article will guide you through the necessary cleaning routines and their frequencies to keep your machine in top condition.

Importance of Regular Cleaning

Cleaning your laser engraver machine is crucial for several reasons. When the machine operates, it generates a significant amount of dust, debris, and fumes. These byproducts can accumulate on various components, leading to reduced efficiency, poor engraving quality, and even potential damage. Regular cleaning helps to maintain the machine’s performance and prevents costly repairs.

Daily Cleaning Tasks

Lens and Mirrors

The lens and mirrors are critical components of a laser engraver machine. Dust and debris can accumulate on these surfaces, affecting the laser beam’s focus and power. It is recommended to clean the lens and mirrors daily or after every use. Use a soft, lint-free cloth and a suitable cleaning solution, such as acetone or IPA, to gently wipe these components.

Work Area

The work area of the laser engraver machine should be cleaned daily to remove any debris and residue from the engraving process. This prevents the buildup of materials that could interfere with the machine’s operation. Use a vacuum or a soft brush to clean the work area thoroughly.

Weekly Cleaning Tasks

Guide Rails

The guide rails are responsible for the smooth movement of the laser head. Over time, dust and debris can accumulate on the rails, causing friction and reducing the machine’s precision. Clean the guide rails weekly using a cotton cloth to wipe off any dust and old lubricating oil. After cleaning, apply a fresh layer of lubricating oil to ensure smooth operation.

Exhaust System

The exhaust system of a laser engraver machine plays a vital role in removing fumes and smoke generated during the engraving process. A clogged exhaust system can reduce its efficiency and pose a fire hazard. Clean the exhaust system weekly by removing the exhaust pipe and fan, then use a brush or compressed air to remove any accumulated dust and debris.

Monthly Cleaning Tasks

Cooling System

The cooling system, whether it’s a water chiller or a fan-based system, is essential for maintaining the laser tube’s temperature. Inspect and clean the cooling system monthly to ensure it is free of any blockages or contaminants. For water chillers, check the water quality and replace it if necessary. For fan-based systems, clean the filters and ensure proper airflow.

Screws and Fasteners

Over time, the screws and fasteners on a laser engraver machine can become loose due to vibrations and regular use. Inspect and tighten all screws and fasteners monthly to maintain the machine’s stability and prevent any mechanical issues.

Quarterly Cleaning Tasks

Laser Tube

The laser tube is the heart of the laser engraver machine. It requires periodic inspection and cleaning to ensure optimal performance. Every three months, inspect the laser tube for any signs of wear or damage. Clean the tube’s exterior with a soft cloth and ensure that the cooling system is functioning correctly.

Electrical Components

The electrical components of a laser engraver machine, such as the power supply and control board, should be inspected and cleaned quarterly. Ensure that all connections are secure and free of dust. Use compressed air to clean the electrical components and prevent any potential issues caused by dust buildup.

Conclusion

Regular cleaning and maintenance of your laser engraver machine are essential for its longevity and optimal performance. By following the recommended cleaning schedules for daily, weekly, monthly, and quarterly tasks, you can ensure that your machine operates efficiently and produces high-quality engravings. Remember, a well-maintained laser engraver machine not only extends its service life but also saves you from costly repairs and downtime.