do laser cutter and engraver machines cut hardboard

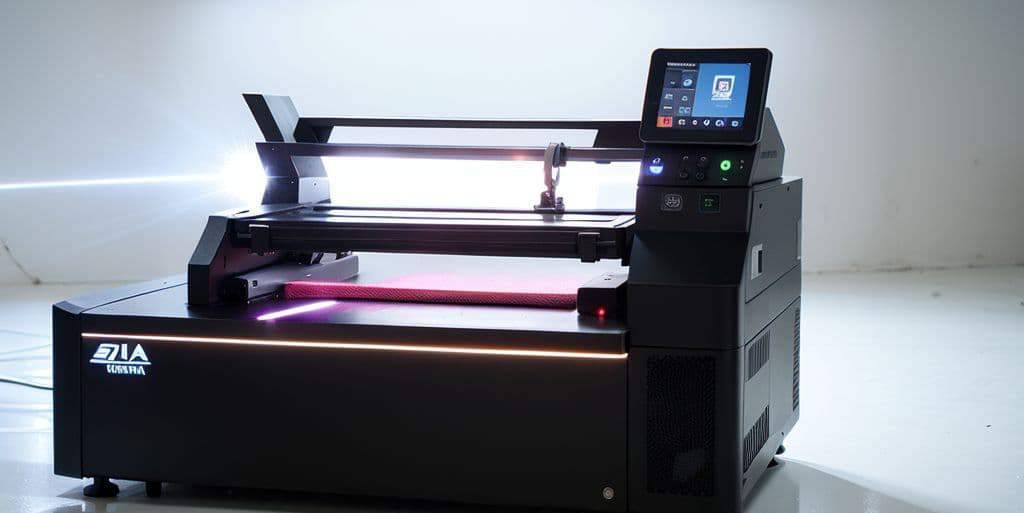

In the realm of modern manufacturing and crafting, the versatility of a laser engraver machine is unparalleled. These machines have revolutionized the way we approach cutting and engraving various materials, including hardboard. But how effective are laser cutter and engraver machines when it comes to cutting hardboard? Let’s delve into the specifics.

Understanding the Capabilities of Laser Engraver Machines

Precision and Accuracy

One of the standout features of a laser engraver machine is its precision. These machines utilize focused laser beams to cut through materials with remarkable accuracy. When it comes to hardboard, this precision ensures clean cuts without frayed edges, which is crucial for both aesthetic and functional purposes.

Versatility in Material Handling

Laser engraver machines are designed to handle a variety of materials, from delicate fabrics to sturdy metals. Hardboard, a dense and durable material, falls comfortably within this range. The ability to adjust the laser’s intensity and speed allows for customized cutting and engraving, making these machines highly versatile.

How Laser Cutter and Engraver Machines Work on Hardboard

Cutting Process

The cutting process involves directing a high-powered laser beam onto the hardboard. The laser’s heat vaporizes the material along the designated path, resulting in precise cuts. The key to successful cutting lies in the machine’s settings, which must be adjusted based on the thickness and density of the hardboard.

Engraving Process

Engraving hardboard with a laser engraver machine is equally efficient. The laser beam etches the surface of the hardboard, creating intricate designs and patterns. This process is controlled by software that guides the laser’s movement, ensuring consistency and detail in the engravings.

Advantages of Using Laser Engraver Machines for Hardboard

Efficiency and Speed

Laser engraver machines are known for their speed and efficiency. Compared to traditional cutting methods, these machines can complete tasks in a fraction of the time. This efficiency is particularly beneficial for large-scale projects involving hardboard.

Minimal Waste

Another significant advantage is the minimal waste produced. The precision of the laser cuts reduces the amount of excess material, making the process more cost-effective and environmentally friendly. This is a crucial consideration for industries focused on sustainability.

Challenges and Considerations

Initial Investment

While the benefits are substantial, it’s important to consider the initial investment required for a laser engraver machine. These machines can be costly, and the expense may be a barrier for small businesses or hobbyists. However, the long-term savings and efficiency gains often justify the upfront cost.

Maintenance and Safety

Regular maintenance is essential to keep a laser engraver machine in optimal condition. Additionally, safety precautions must be observed to prevent accidents. Proper training and adherence to safety guidelines are crucial when operating these powerful machines.

Conclusion

In conclusion, laser cutter and engraver machines are highly effective tools for cutting and engraving hardboard. Their precision, versatility, and efficiency make them a valuable asset in various industries. While there are considerations such as initial investment and maintenance, the benefits far outweigh the challenges. For anyone working with hardboard, a laser engraver machine is an indispensable tool that enhances both productivity and creativity.