how to laser engrave acrylic

Introduction

Acrylic, known for its clarity and versatility, has become a popular material in various industries. Laser engraving on acrylic offers precision and intricate designs that traditional methods cannot achieve. This article delves into the complexities of laser engraving acrylic, providing a comprehensive guide for both novices and seasoned professionals. By mastering the techniques of laser engrave cutting, one can unlock endless creative possibilities.

Understanding Acrylic Material

Acrylic, chemically known as polymethyl methacrylate (PMMA), is a transparent thermoplastic often used as a lightweight or shatter-resistant alternative to glass. Its properties make it ideal for laser engraving and cutting. The material’s response to laser beams allows for precise manipulation without causing significant thermal damage or warping.

There are two main types of acrylic: cast and extruded. Cast acrylic is preferred for engraving because it produces a frosted appearance when engraved, offering high contrast. Extruded acrylic, on the other hand, tends to melt during engraving, resulting in less desirable outcomes. Understanding the differences between these types is crucial for optimal results in laser engrave cutting.

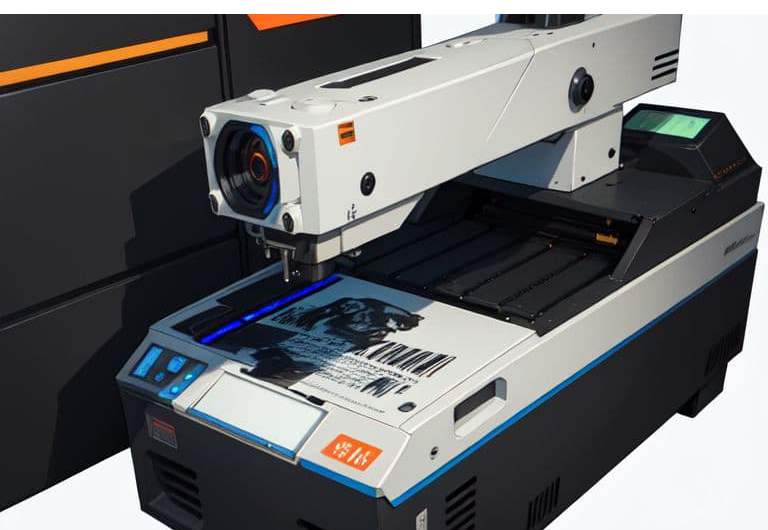

Choosing the Right Laser Engraving Machine

Selecting an appropriate laser engraving machine is pivotal. CO2 lasers are commonly used for acrylic due to their efficiency and precision. These machines vary in power, typically ranging from 30W to 150W. A higher wattage allows for faster engraving and cutting but may sacrifice detail. Conversely, a lower wattage offers finer detail at the expense of speed.

Key factors to consider include the machine’s resolution, speed, and compatibility with design software. Modern laser engravers often come with user-friendly interfaces and support various file formats, enhancing the workflow. For those seeking to invest in equipment, understanding how to buy a laser engraving machine that fits specific needs is essential.

Preparing Your Design

Software Selection

Design preparation begins with choosing the right software. Programs like Adobe Illustrator, CorelDRAW, and AutoCAD are widely used due to their robust vector graphics capabilities. Vector files are preferred because they ensure scalability without loss of quality, which is crucial for precision in laser engraving.

Design Optimization

Optimizing your design involves setting correct line weights, resolving overlapping paths, and ensuring that all elements are properly configured for engraving or cutting. Thin lines may not engrave effectively, and overlapping paths can cause the laser to pass multiple times over the same area, leading to inconsistent results.

Raster vs. Vector Engraving

Understanding the difference between raster and vector engraving is critical. Raster engraving involves engraving by moving back and forth across the material, much like an inkjet printer, suitable for filling areas and creating images. Vector engraving follows the paths of the design, ideal for cutting outlines and detailed line work.

Machine Setup and Calibration

Proper machine setup ensures safety and optimal results. Begin by securing the acrylic sheet on the engraver’s bed to prevent movement. Focus the laser lens according to the manufacturer’s instructions, as incorrect focusing can lead to distorted engravings or fire hazards.

Calibration tests are recommended to determine the ideal laser settings for your specific acrylic type. This includes adjusting the power, speed, and frequency. A common practice is to create a test grid that varies these parameters to visually assess the engraving quality.

Executing the Engraving Process

Setting Laser Parameters

Laser parameters significantly affect the engraving outcome. For acrylic, a lower power setting with a higher speed often yields the best results for engraving, while higher power and lower speed are suitable for cutting. Manufacturers usually provide recommended settings, but adjustments may be necessary based on specific project requirements.

Air Assist and Ventilation

Utilizing air assist helps to prevent flare-ups and removes debris from the engraving surface. Proper ventilation is essential to eliminate fumes generated during the process, as acrylic can produce harmful gases when heated. Ensuring a clean working environment contributes to both safety and the quality of the engraving.

Monitoring the Process

Continuous supervision during engraving is crucial. Monitor the machine for any signs of malfunction or material issues. Being attentive allows for immediate intervention if problems arise, thereby protecting both the equipment and the workpiece.

Post-Engraving Finishing Techniques

After engraving, certain finishing techniques can enhance the aesthetic of the acrylic piece. Removing protective backing and cleaning the surface with non-abrasive cleaners prevent scratches. For edges that have been cut, flame polishing can restore clarity, though it requires skill to avoid warping the material.

Applying paints or fillers to engraved areas can add color and depth. When doing so, ensure the materials used are compatible with acrylic to prevent chemical reactions that could damage the piece.

Common Challenges and Solutions

Surface Burning and Flashback

Surface burning can occur if the laser power is too high or the speed is too low. Adjusting these parameters can mitigate burning. Flashback, caused by the laser beam reflecting off the machine bed back onto the material, can be reduced by using a honeycomb or pin table to minimize contact points.

Inconsistent Engraving Depth

Inconsistencies in engraving depth may result from an uneven workpiece or improper focus. Ensure the acrylic sheet is flat and the laser is correctly focused across the entire engraving area. Regular maintenance of the laser optics can also prevent this issue.

Edge Quality Issues

Poor edge quality when cutting acrylic is often due to incorrect speed and power settings. A slower speed with higher power typically produces smoother edges. Additionally, ensuring that the laser beam is clean and properly aligned contributes to optimal edge quality in laser engrave cutting.

Advanced Techniques

For experienced users looking to push the boundaries, techniques such as 3D engraving and layered assembly can create impressive effects. 3D engraving involves adjusting the laser’s power during the engraving process to produce varying depths, adding a tactile dimension to the work.

Layered assembly involves engraving or cutting multiple acrylic pieces that are then assembled to create complex structures or images. This method requires precise alignment and design planning but can result in stunning visual displays.

Safety Considerations

Safety should always be a priority when operating laser engraving equipment. Protective eyewear rated for the laser’s wavelength is essential to prevent eye damage. Awareness of fire hazards, proper ventilation to avoid inhalation of fumes, and adherence to manufacturer guidelines are fundamental practices.

Regular maintenance of the equipment, including cleaning lenses and removing debris, not only extends the machine’s lifespan but also maintains operational safety and efficiency.

Applications of Laser Engraved Acrylic

Laser engraved acrylic finds applications across various fields. In the signage industry, it provides high-quality, durable signs with intricate details. In architecture, it is used for model making and decorative elements. The advertising sector utilizes laser engraved acrylic for displays and promotional materials.

Artists and designers employ this technology to create custom art pieces, jewelry, and home décor items. The precision of laser engrave cutting enables the production of unique and personalized products that meet specific client needs.

Economic Considerations

Investing in laser engraving technology involves analyzing the cost-benefit ratio. Initial costs include the purchase of the machine, setup, and training. Operating costs encompass materials, maintenance, and energy consumption. However, the ability to offer high-value services can lead to a substantial return on investment.

Understanding market demand and identifying niches where laser engraved acrylic products are sought after can enhance profitability. Whether in custom gift markets or industrial components, the versatility of laser engraving opens numerous business opportunities.

Future Trends in Laser Engraving

Advancements in laser technology continue to expand capabilities. Developments in fiber lasers and ultrafast lasers offer improved precision and speed. Integration with automation and digital technologies enables mass customization and scalability.

Sustainability is becoming increasingly important, leading to innovations in energy efficiency and environmentally friendly materials. Staying informed about technological trends ensures that businesses and practitioners remain competitive and meet evolving customer expectations.

Conclusion

Mastering the art of laser engraving acrylic combines technical knowledge with creative expression. From selecting the right material and equipment to refining techniques, attention to detail at each step results in high-quality engravings. Embracing continuous learning and innovation keeps practitioners at the forefront of the industry.

By leveraging the potential of laser engrave cutting, individuals and businesses can produce exceptional products that resonate with clients and stand out in the marketplace.