what is a good laser engraving machine

What is a Good Laser Engraving Machine

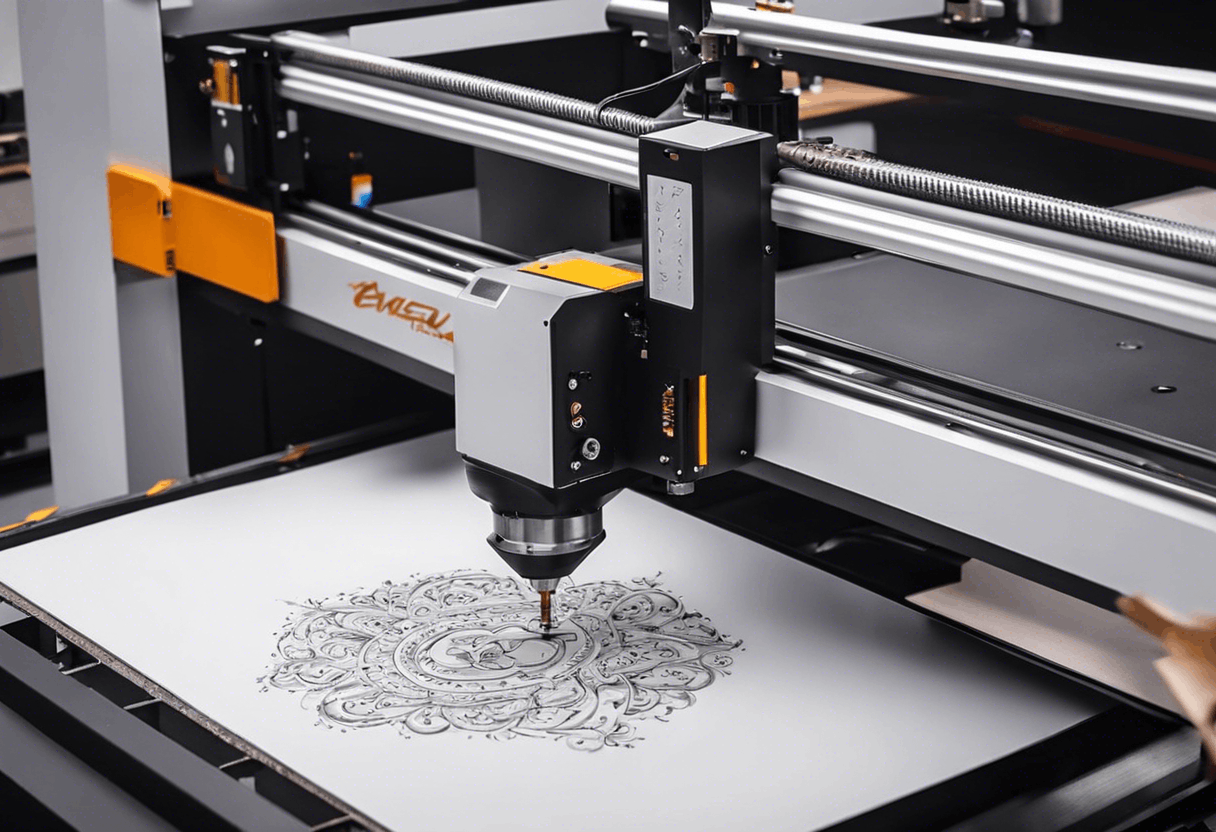

Engraving refers to a type of printing done on metal plates. Lines are cut on the metal where the ink will be held. A laser engraving machine uses laser technology to engrave on a metal surface or any other surface. They are widespread in industries that want to label/mark manufactured items and are known for their precision and smooth finishes. This article will look at everything businesses should know about laser engraving machines.

Demand and Market Share for Laser Engraving Machines

In 2020, the global market share of laser engraving machines was US$ 2.76 billion. The adoption of laser engraving machines is driven partly because of the benefits they offer in the automation of industries. The most notable of these is the medical field, which has recently experienced an upward surge in laser engraving technologies. Their reliability, effectiveness, and uniqueness of production are reasons that will drive their adoption even further.

Factors to Consider When Buying a Laser Engraving Machine

Throughput of the Engraving Machine

It refers to parts processed per hour. The speed with which the engraving machine works will directly affect business sales, whether the volume of work is low or high. This, in turn, gives the business an edge in that it can offer lower prices to its customers.

Table Size of Processing

The table size determines the size of the object engraved. A smaller table size translates to smaller objects engraved, while a more extensive table will allow bigger objects to be engraved. The table sizes range from 300mm x 200mm while larger tables can be as big as 1600mm x 900mm. Depending on the object size businesses want to engrave, they can choose a suitable engraving machine.

Applicable Material of the Engraving Machine

Engraving machines can work with several materials. Plastic, paper, metal, acrylic, and wood can be used during engraving. Businesses should consider the material they will be engraving before purchasing because engravers specialize in different materials.

Brand of Key Components

Before businesses purchase an engraving machine, they should consider well-established and reputable brands. This is to find quality and market-approved engraving machines. Besides this, a clear on-site demonstration of the engraver should be made to businesses to ascertain its effectiveness.

Types of Laser Engraving Machines

There are several types of laser engraving machines based on their mode of operation. They are listed below.

Etching

Laser etching occurs when the laser beam comes into contact with the material and melts it.

Deep Laser Engraving

This type of engraving involves removing material to create a cavity that can be seen and felt.

Laser Ablation

Laser ablation is the process of removing material from a solid surface by irradiating it with a laser beam.

The Target Market for Laser Engraving Machines

Laser engraving machines are expected to grow at a CAGR of 7.5% until 2029. This will bring its market share to US$ 5.3 billion.

North America and Canada are expected to see substantial growth in their laser engraving machines markets because of strict health regulations on medical engraving equipment and surgical equipment. The Asia Pacific region will have the largest share of the global laser engraving machines market and is expected to continue dominating.

Conclusion

Engraving is an art that has been around for some decades. Known for the permanent marks that they leave, laser engraving machines have grown in popularity in many industries. Businesses can choose between etching, ablation, and engraving laser machines depending on the application required.